We’ve spoken before about emulsifiers. These are the cosmetic additives which help to combine oil and water into a stable lotion or cream. Today, I want to take a deeper dive into a specific class of emulsifiers, because they offer enhanced effects beyond simple stability of the product. These emulsifiers are known to form “Lamellar Liquid Crystals”, or LLCs.

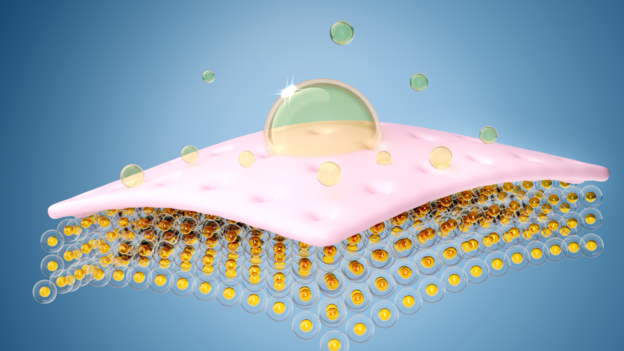

The simplest way to imagine a lamellar liquid crystal is to picture a cheese sandwich. The sandwich has bread on the top, bread on the bottom, and cheese in the middle. Now, imagine that we stack several hundred, even thousands of cheese sandwiches all on top of each other. We now have separate units (sandwiches) which have arranged themselves into a type of long-range order (the stack of sandwiches). There’s nothing physically connecting sandwich 1 to sandwich 2, it just happens spontaneously if the conditions are right. To bring the analogy home, now imagine that the bread represents hydrophilic (water-loving) parts, and the cheese represents hydrophobic (water-fearing) parts. When you get this type of stacked sandwich-like structure in cosmetics, we say that the product contains “lamellar liquid crystals.”

Liquid crystals are fairly unique phases. They’re not quite a solid, but they’re not quite a liquid. Imagine cheese that’s just at its melting point; it’s not quite solid, and it’s not a flowing liquid like very hot cheese. It’s in this “in-between” state where it’s kind of solid but you can still move it around a little bit while keeping its shape. With liquid crystals, the “lamellar” type is shaped like our sandwich analogy. They are layers of molecules that stack on top of each other, where the “bread” part loves water and the “filling” part avoids water.

These lamellar structures only show up under certain conditions. You need specific fats or surfactants, a watery environment, and just the right additives before LLCs will form. The reason the molecules wait to form this structure is pretty simple: the water-loving parts (the bread) want to face the water, while the water-hating parts (the cheese) want to avoid it. It’s a bit of a tug of war, and a convenient way to please both parts is for the sandwich to adopt this stacked lamellar structure. With other sandwiches.

It can be difficult to think of something that is halfway between a solid and a liquid. Let’s try another analogy. Pretend you’re at a beach party with a lot of friends. Some people absolutely love the water and so they desire to be as close to the sea as possible (water-lovers). Other people might be afraid of the strong ocean currents, so they relax under a beach umbrella (water-haters). If someone were to force everyone to stand in a line for a group photo, the people who love water would stand closer to the sea, and the ones who don’t enjoy the water would stand in front of them, farther from the sea. This results in a structured formation. Individual units (people, sandwiches, molecules) are aligning themselves into a specific orientation, even though they’re not physically connected to each other. It’s a mutual group decision driven by preferences and having enough energy to move around.

So, why do we care, as cosmetic formulators? Well, the special arrangement of LLCs allows them to have some neat and important features.

The first is to enhance barrier formation. LLCs can act as a protective wall or barrier. Because their layers are very ordered, they can help to provide a barrier on the skin, preventing moisture loss and protecting against external contaminants. Since they can incorporate both water-loving and water-hating materials, they’re ideal as a delivery agent for various cosmetic actives into the skin. The structure helps to ensure that all the ingredients are released slowly and effectively, rather than all at once.

LLC lotions/creams tend to have a smooth and rich feel to them. Just by choosing the right emulsifier and treating it correctly, we can improve the skin feel of our product with no added cost. This is just a free phenomenon, and you should take advantage of it! LLCs feel more luxurious – smooth, rich, easily spread – on the skin, and are very hydrating.

Because they have structure to them, LLCs can help to stabilize emulsions. Emulsions (mixtures of oil and water) can sometimes separate or become unstable over time because oil and water don’t like to mix. However, the presence of lamellar structures can hold these mixtures together for longer. The oil would have to escape the energetically favoured positioning within the LLC in order to coalesce with other oil droplets, which is usually what breaks an emulsion.

Beyond just the feel of the product, lamellar structures often show a gloss / shine that you don’t see with non-LLC emulsifiers. This can add to the overall appeal of the cosmetic product. And since the ingredients must escape the stack of molecules to be delivered to the skin, LLC-emulsified products tend to have a more controlled, extended-release of the actives into the skin. This can be very useful when a needed ingredient is particularly irritating if used all at once; we can spread out its rate of delivery, and spare the skin some irritation.

So, how can you make LLCs in your products? The key is in selecting the correct emulsifier, and then treating it correctly. Here are some examples of emulsifier systems known to form LLCs:

Lecithin. This is a natural phospholipid which forms lamellar structures very easily. Lecithin is not a great emulsifier, but it sometimes can find a use in a cosmetic product.

Non-ionic emulsifiers like polysorbates and sorbitan esters, along with polyglyceryl esters, are known to form liquid crystal structures. The presence of fatty alcohols and fatty acids like stearic acid can promote this structure formation. Olivem 1000 is a very good example of an emulsifier that has the potential to form LLCs. The manufacturer of your emulsifying system will be able to give you more information as to whether it is known to form liquid crystals.

The second important point when using liquid crystal emulsifiers is that you must give them a chance to form. Traditional emulsification has a hot water phase being homogenized while the hot molten oil phase is gently drizzled into the water flask. This homogenization can continue for some time.

With LLC emulsifiers, it’s still useful to use that initial homogenization but then during the cool-down phase, you need to switch to a gentler kind of stirring. These molecules are shuffling around trying to arrange themselves into a pattern. If you stir them too rapidly during cooldown, the molecules get swept away and the liquid crystals won’t form. You’ll end up with an emulsion that doesn’t have the same benefits. I usually recommend switching to 150 RPM paddle stirring (or equivalent) after the initial homogenization combination. It gives the emulsifier and fats time to orient themselves in this stacked LLC fashion and gives us extra benefits just by putting a little thought into the formulation methodology.

To conclude, lamellar liquid crystals are special molecular sandwiches that play an important role in cosmetics. They offer structure, stability, and enhanced delivery of the other ingredients. They act as a bridge between water-loving and water-hating components. They heighten the effectiveness of the product and make it feel better on the skin. I encourage you to research this issue further and to try to achieve this condition in the next product you formulate. It offers only benefits, no drawbacks, and you need an emulsifier anyway so there are no added costs. It just takes careful formula design and then a light touch when assembling. With a little effort, you can have lamellar liquid crystals working behind the scenes to give your customers a heightened experience.